-

Noisy Duet Washer

This is a noisy Duet style Whirlpool front loading washer. It begins to make a knocking sound as the unit begins to wind up on the spin cycle. It is not the normal rumbling sound of a bad bearing. To my ear it sounds like a loose pulley wheel – but I’ve tightened the pulley nut as tight as I can, and the sound is still the same. When I look at the edge of the pulley, I notice that it is not completely round – it was a wobble to it. So I will try replacing the pulley to see if that fixes the sound. If not, I guess it will be the rear drum bearing.

Update: this one did end up being a rear drum bearing. Usually the rear bearing makes a rumbling or grinding noise – this noise was different than the norm. But it is fixed.

-

Hazards of the Job

Getting a treatment on my chronic tennis elbow caused, not by tennis strangely enough, but by using a screwdriver too much with my right hand. Need to become a lefty. -

LF Code on a Whirlpool Duet Style Front Loading Washer

The unit will not fill and is flashing up the code LF. LF stands for Long Fill and can be triggered by anything from a water supply problem to pressure switch problems. In this case there was no water coming to the unit … so the fill was extra long! Lol.

EDIT: Other things to check for with a LF code:

1. Did someone tell you that you could use just cold water on your washer? I’ve noticed a lot of people trying to use their washers with only a cold water hookup. The various new ‘cold water’ detergents have not helped either. Your Duet washer will not work properly with only the cold water hooked up. It still measures the temperature of the water entering the machine, and if it is too cold it will still add some hot to bring the water temp up a bit. I think it tries to make it around 68 deg. Here in Canada, our tap water can be down as low as the low 40’s F – so a fair amount of hot water is required to bring the temp up. The next question I hear you asking is … why? I wan’t to use just cold water. Well, actually, no you do not. Do this as an experiment. Take the cold water from your tap and measure the temp. If it is below 50 degrees, add a handful of detergent and see what what happens. It will not dissolve … or if it does it will be sort of thick. Soap’s need a certain degree of warmth to activate and tap cold is often too cold to do that. Your clothes will not be washed properly in this situation.

2. Anti-flood hoses. These hoses were designed to shut off a flow of water if they burst. So … a couple of things about these. They only come in braided stainless steel. I’ve never seen one of those hoses burst. They are wrapped in a sheath of stainless steel metal … they can’t burst. So why the anti-flood valves built in? Answer: so they can charge you more. Next: those hoses are famous for triggering off the anti-flood valve on just a regular washer fill. Often it will be just one hose that it happens on, but that means that when it is calling for water from that hose and not getting it, the LF code will be triggered. This most often shows up on the rinse cycle.

3. If you are getting LF and water is entering the machine … and creeping up the glass on the door, then you have a water pressure switch or pressure hose problem. Check out this post for one of the more common problems I see with the pressure hoses. In this case, water is actually coming in, the machine is just not able to sense it coming in.

4. Kinked fill hose?

5. Taps turned off?

6. Are your feet wet? Is the water coming in but draining out via some major leak on the bottom? lol.

EDIT 2: See my post F20 On A Duet Washer for another very common cause of LF Codes.

If any of these ideas helped you or if you found it to be something else, please add a comment here for me. I learn as much from others as I do from my own observations!

-

Leaking Water Dispenser

This is a brand new Kitchen Aid refrigerator. The water dispenser leaks anywhere from 2 drips to a couple of dozen drips. This problem is being caused by air entering into the water system somewhere. You can tell that it is air in the system by the little ‘spurt’ that you can see about 1/2 a second into the video. This air bubble happens every time the water dispenser paddle is pushed. I traced the air bubbles back as far as the tank in the fresh food section – I can see bubbles entering the tank when I call for water. This eliminates everything after the water tank as the source of the air. The parts left are the water filter, filter housing, water valve and interconnecting tubing. I’m leaning toward the filter housing being the problem, so I will try that first.

-

Overflowing Icemaker

This bottom mount Whirlpool fridge was making ice non-stop. After removing all the ice, I found the ice-maker shutoff arm was no longer inserted into the ice-maker. I reinstalled it and now this unit should shut off when the bucket is full. This problem was probably caused by putting a box on top of the ice bucket and then shutting the door.

-

Sub Zero Breaks the Union at Madison Plant

Sub Zero / Wolf has broken the back of the plant union by threatening tomove the plant to Kentucky. The union took the threat seriously enough that they actually agreed to a 20% wage cut and a 5 year wage freeze. This is virtually unprecidented in appliance manufacturing with most plants simply announcing moves to Mexico or Asia. The union has little to do or say with these decisions.

While most bloggers are suggesting the this is evil corporate tactics, I think that they have actually done the workers right. In the current recession, the demand for high end appliances has really dried up. Sub Zero / Wolf had 2 options … reduce costs or shut down. They gave the union workers the option of helping reduce costs or hit the unemployment lines. They chose the former. Good for them and good for Sub Zero. Hopefully, ten years from now when the US is on the rebound, Sub Zero remembers the commitment that workers showed to the company and rewards them when they can.

Read the whole story at Channel3000.com.

-

Integrated Washing Machines

Integrated washing machines are becoming more popular with the explosion of front loaders on the market these days. There are several ways to build in your washing machine (making it integrated) which we will discuss in more detail below. As most manufacturers are making some sort of front loader, you will have a choice of many different brands.

There are many advantages to integrating your washing machine. There are also a few substantial disadvantages which we will also mention.

The main advantage of building in your washer and dryer is aesthetic. A built in washer can be put pretty much anywhere including your kitchen, your bathroom, a bedroom or a dedicated laundry room. The typical installation usually involves integrating the washer and dryer into the cabinets under a counter-top. This hides the appliances away and makes for a very clean and uncluttered room. This type of integration means that the space on top of the machines becomes much more useful. This is especially important in kitchen or bathroom installations where you need all the counter space you can get. When installing in cabinets under a counter-top, make sure that you configure the doors to open in a ‘french door’ style. That is, they both open in opposite directions making the space between the washer and dryer unimpeded. You should also make sure that the appliance doors open in opposite directions as well. Typically the dryer door swing can be changed, so make your decision on where to place them based on the way the washer door opens.

The main advantage of building in your washer and dryer is aesthetic. A built in washer can be put pretty much anywhere including your kitchen, your bathroom, a bedroom or a dedicated laundry room. The typical installation usually involves integrating the washer and dryer into the cabinets under a counter-top. This hides the appliances away and makes for a very clean and uncluttered room. This type of integration means that the space on top of the machines becomes much more useful. This is especially important in kitchen or bathroom installations where you need all the counter space you can get. When installing in cabinets under a counter-top, make sure that you configure the doors to open in a ‘french door’ style. That is, they both open in opposite directions making the space between the washer and dryer unimpeded. You should also make sure that the appliance doors open in opposite directions as well. Typically the dryer door swing can be changed, so make your decision on where to place them based on the way the washer door opens.The main disadvantage to integrating your washing machine and dryer is that it makes service and maintenance extremely difficult. This is especially true if the room where they are integrated is very small preventing them from even being pulled out easily. Often integrated washing machines need to be plugged in and hooked up to water while taken apart for the service man to figure out what is wrong with it. If the hoses and electrical connections are too short, then often the service becomes very long and involved which can drive up the cost of your service call. (Of course, your new washer and dryer will never require service … right?) For the dryer, the vent hose needs to be periodically cleaned. Plus when the machine is pushed back, you need to ensure that the hose is not crushed or collapsed in any way. This is difficult to do and check if you have an integrated dryer.

Closet Integrated Washing Machines

This type of integration is probably the most common. Many condo’s and smaller homes use a small closet for the washer and dryer. Usually, this means stacking the dryer on top of the washer and then building them in as a pair. Most often a stacking kit is required to safely install the dryer up on top of the washer. This is a very clean install and a very economical use of space if you have little space to spare. While some closets can accomodate a full size pair stacked up, more often this installation is used with the smaller washer and dryers to fit within a narrow closet space. The main issues of consideration are the water supply, drain and venting for the dryer. If you can find a solution to those issues, then this is a wonderful way to integrate your washing machine and dryer.

Cabinet Integrated Washing Machines

This is another way of integrating your laundry pair. This usually involves installing them side by side under a counter-top. This is most often the best way to use the space in a laundry room the is long but narrow. This is also a popular way of integrating the washer into a bathroom or kitchen. Again ease of use is greatly increased if you make sure that the doors to each cabinet and each appliance opens outward so the the space between the two appliances is clear. This makes for easy moving of clothes from the washer to the dryer.

One-piece Stackers as Integrated Washing Machines

Stackers as they are called in the industry are usually one-piece machines that often incorporate a top-loading washer beneath with the dryer above. This is an ideal design for closet installation and is also very popular in smallish condo’s and apartments. The major drawback is again service. They can be very difficult to service and if one ends up needing replacement, then you have to buy a whole new stacker as they cannot be purchased separately. However, with proper care these machines should last at least 15 years making this less of an issue.

Integrated washing machines and integrated dryers are a wonderful way to work in a small space. Proper preparation and planning can make the installation and maintenance of these units easier and you will certainly appreciate the extra space that you free up by building them in.

-

Maytag Fridge Recall Due To Fire Hazard

NOTE: If you live in Brampton, Ontario and are concerned that your fridge might be affected, please do not hesitate to contact me to chat about it.

Hazard Identified

An electrical failure in the relay, the component that turns on the refrigerator’s compressor, can cause overheating and pose a serious fire hazard.Two incidents and no injuries have been reported in Canada. Outside of Canada, Maytag has received 41 reports of refrigerator relay ignition, including 16 reports of property damage ranging from smoke damage to extensive kitchen damage.

Corrective Action

Consumers should immediately contact Maytag to determine if their refrigerator is included in the recall and to schedule a free in-home repair. Consumers should not return the refrigerator to the retailer where it was purchased.For more information, contact Maytag toll-free at (866) 533-9817 anytime, or visit the firm’s Web site at www.repair.maytag.com. Click Here to see if your fridge is affected.

Number Sold

Approximately 193,500 units were sold at department and appliance stores and by homebuilders in Canada.

Time Period Sold

The recalled products were sold from January 2001 through January 2004.

Breakdown of Model Affected

Side by Side Refrigerators with Serial Numbers ending in: AA, AC, AE, AG, AJ, AL, AN, AP, AR, AT, AV, AX, CA, CC, CE, CG, CJ, CL, ZB, ZD, ZF, ZH, ZK, ZM, ZQ, ZS, ZU, ZW, ZY, ZZ AND Model Numbers beginning with: ARS, CS, JC, JS, MS, MZ, PS

Top Mount Refrigerators with Serial Numbers ending in: AA, AC, AE, AG, AJ, AL, AN, AP, AR, AT, AV, AX, ZK, ZM, ZQ, ZS, ZU, ZW, ZY, ZZ AND Model Numbers beginning with: AT, CT, MT, PT.

-

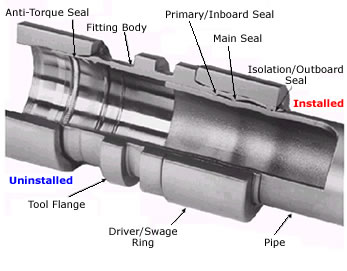

Lokring Compression Fittings

Are we finally going to get away from soldering and all the problems that are associated with it? According to this post at Technician Brian.com – Sub Zero is demonstrating Lokring fittings. We’ve seen a couple of compression fittings on the Whirlpool fridges but no information has been presented on how to make the connection in the field. I would love to be able to use this, especially for a process stub to check pressures, etc.

Are we finally going to get away from soldering and all the problems that are associated with it? According to this post at Technician Brian.com – Sub Zero is demonstrating Lokring fittings. We’ve seen a couple of compression fittings on the Whirlpool fridges but no information has been presented on how to make the connection in the field. I would love to be able to use this, especially for a process stub to check pressures, etc.As an aside, when guys find leaks on the Whirlpool compression fittings, they’ve been cutting them out and joining the ends together with a sleeve. Twice, I have simply heated the compression and soldered completely over it and not had any problems. It looks kind of ugly, but it works for me.

-

Raleigh N.C. Bans Garbage Disposers

The following story is from WRAL.com.

Raleigh began disposing of garbage disposals Monday, banning new or replacement installations. But opponents to the ban plan to put the City Council through the grinder over the move.

The disposal ban, which the City Council approved two weeks ago, is among the first in the country. Violators face fines of up to $25,000 per day.

Under the ban, homeowners can continue to use existing disposals, but no new devices can be installed and existing ones can’t be replaced when they quit working. Homes that have obtained city permits and are already under construction will be allowed to keep their disposals, officials said.

Some builders and residents said they would protest the disposal ban at Tuesday’s council meeting.

“I don’t think this has been handled properly at all,” resident Caroline McCall said. “I feel that it was a knee-jerk reaction.”

City officials said putting food and grease through a disposal and into the municipal sewer system clogs the lines and frequently causes back-ups and overflows.

Raleigh has had almost 100 sewer overflows in the last three years, with raw sewage sometimes flowing into area streams. The state Division of Water Quality has threatened to fine the city for each overflow if it doesn’t correct the problem.

Mayor Charles Meeker said disposals also waste about 500,000 gallons of water a day citywide.

“I suspect that, once the public understands the environmental problems and the water wasted, they’ll understand this is the right thing to do,” Meeker said.

McCall and developer Richard Gaylord said they don’t understand the city’s action.

“They have no way of knowing if the grease spill (causing a sewer overflow) came from a garbage disposal or where the grease came from,” McCall said.

“I don’t think people had forewarning,” Gaylord said. “I think there is some confusion out there as to how this will be implemented and what the parameters are.”

The ban also has come under fire from City Councilman Philip Isley, who missed the March 4 vote on the issue, and from the mayors of Garner, Knightdale, Rolesville, Wake Forest, Wendell and Zebulon.

The six towns are part of the municipal water and sewer system, so Raleigh’s regulations apply to residents in those towns as well. The other mayors said they should have been consulted before Raleigh enacted the disposal ban.

Isley said he plans to ask council members to take a step back and study the issue in committee, but he said he might not have the votes to support the move.

My (Neighbour’s Appliance) opinion is that this will not stop people from pouring grease down their sinks. People have been doing it since we got indoor plumbing and will continue to do it until indoor plumbing is somehow eliminated.