Blown MCU Boards in Whirlpool Duet Washers

EDIT: I received the following comment from David which may explain the ‘soapy’ looking residue. “As an engineer that works at a place that builds up circuit boards for other companies, I can say that the ‘soapy’ residue looks more like the end result of typical board wash at the end of an assembly line. The wash is meant to make the the solder flux inert. Different types of flux are easier or more difficult to remove completely.”

Original Post:

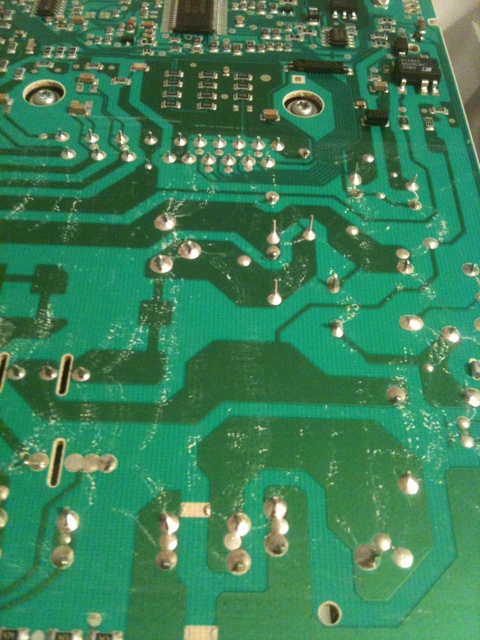

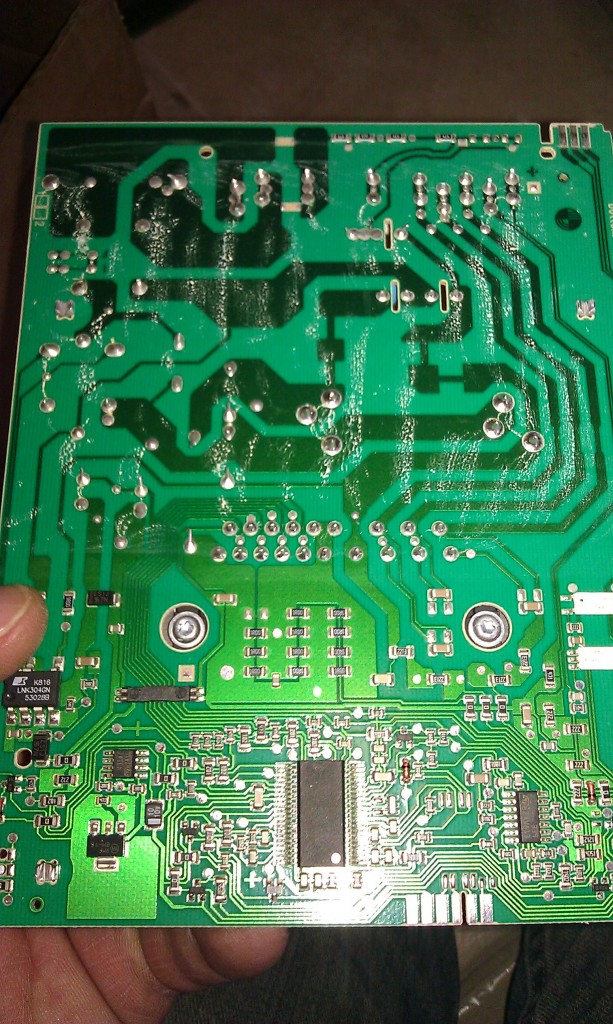

I’m seeing more and more of these Duets with funky MCU (motor control unit) boards. Often the washer will not even lock – just gives 3 beeps. When you disconnect the MCU at the CCU then at least the door will lock and you know you have a MCU problem. In this case, when I pulled the board out of the plastic housing, you can see that there has been soapy condensation dripping down the back of this board. I will keep checking these as I replace them to see if this soap residue is common to all these. FTR – this customer did have HE detergent in the laundry room. That does not mean they’ve always been using it, but right now they are.

EDIT Aug 15/11: Here is another one. You can see the soapy drip trail heading right at the burnt out spot on the board.  EDIT Aug 15/11: Here is another one.

EDIT Aug 15/11: Here is another one.

Edit Sept 30/11: Another one. Multiple trails of soap residue.

Edit May 8/13: More residue trails.

43 Comments

Mike Graf

I am confused to say the least. I have a Whirlpool Duet front loader washer 2011 model I have a F2 E1 code, a locked door at all times, and no operation. I wiggled and checked every connection and plug to no success. I removed the control unit at the top right side under the top cover and it has these soap trails all over it. There is no control unit underneath the basket near the drain filter. I do not see how soapy residue could reach above the basket and contaminate the board, if this is even my problem. I see no burn marks anywhere. I am not sure if the board is good or bad. Any suggestions? Also the door being locked is prohibiting me from obtaining the model number. Is there a way to apply power/ground to open the latch, or is it stuck or faulty do you think. Thanks for any help.

Head Wrench

Those ‘soap’ marks are likely not soap … see my edit at the top of the post from David. The door has a release under the door latch on the inside. I can reach it from on top with the top panel removed pushing my arm down beside the tub. If you can’t reach it that way, you’ll either have to remove the kick panel from the front or the back panel and reach in (depending on the Duet that you have.) Once you get a model number, feel free to post in and I’ll see what else I can tell you.

Will

I have a Whirlpool Front load washer WFW9151YW that works correctly in wash cycle, but when it goes into the spin cycle it senses and out of balance condition and slows the spin cycle down and after several attempts the tub stops and the pump continues to pump until it times out and shuts down. I still have wet clothes in the washer. My next step was to put the machine into a Drain and Spin cycle just to wring out the water before putting them into the Dryer.

I also found if I catch the washer in the last 5 minutes of the spin cycle and push the Start / Paus button and leave the machine off for 1 minute it will reset the controller and try to go into the spin cycle again.

1. The washer work OK when I put it through the Diagnostic Test. Tub fills with water, In the Wash cycle: The tub turns clockwise and counter clockwise, Tub drains out completely, the tub spin cycle went from low to high spin without any issues. I also checked for “Error Codes” on the CCU and found no issues.

2. I removed the door switch and tested it out completely. No Issues.

3. I replaced all the shocks on the tub and tested the machine again, it still registered an out of balance condition and left the clothes in the washer soaking wet

4. I checked the MCU for loos connections, bad capacitors, burned resisters, and diodes. Found no visible problems with the board or motor.

After all this I still have a washer that is not out of balance, but somehow registers an out of balance condition. I would like to know what sensor registers an out of balance condition, so I could adjust or replace this sensor instead just replacing parts. How can I access the program and adjust the high speed of the MCU , Whirlpool WFW9151yw. The washer is not out of balance, but the machine is registering an out of balance condition.

I contacted Whirlpool Co today 3/23/18 at 10:21 this morning and they are lost and I requested that they forward this to one of their Engineers

Head Wrench

1. Check for wrong soap … or old soap.

2. Check the drain for a slow drain.

3. Ohm out the motor

4. Check all wiring from M13 on the CCU all the way to the motor.

5. If all else looks good, I’m inclined to think MCU, but that is just a guess.

David Bailey

As an engineer that works at a place that builds up circuit boards for other companies, I can say that the ‘soapy’ residue looks more like the end result of typical board wash at the end of an assembly line. The wash is meant to make the the solder flux inert. Different types of flux are easier or more difficult to remove completely.

My blown Whirlpool MCU would be impossible to immerse in soap suds unless there was flooding of two inches or more (it’s covered).

None the less, I’m seeing the same thing, blown chip and resistor (fuse?).

Has anyone had this happen and replace the MCU and have it blow again?

Head Wrench

That’s really good info about the board wash. Did not know about that process. I’ve replaced many dozens of those boards with few problems. Did 2 last week. None this week … so far. lol.

Andy

Mine was the same Problem , burned .the chip right there

How to replace that chip?

Does one has prescription for that?

Andy

Mine was the same Problem , burned .the chip right there

How to replace that chip?

Does one has prescription for that?

Head Wrench

I’ve never seen anyone replace blown chips on these. Resoldering burnt out traces is rarely a lasting repair. The only soldering that I’ve seen last is repairs on cold solders.

ChrisD

My trace at the F position was also bad so I soldered a wire across it. That didn’t fix things or was only a partial fix, so I then did what Weig said about baking “the MCU in the oven at 385F for 8 minutes”. That fixed it and it has now worked for 2 weeks. Thanks Weig.

Rich G

The information that I found here was invaluable, so I wanted to say thanks.

Our 6 year old Whirlpool WFW94HEXW2 washer got the F06/E02 and E01 codes. I used this video for disassembly info: https://www.youtube.com/watch?v=-OUUC2ov5u4. The white cover had two obvious burn marks, one located over a tiny flat resistor and one located over a chip. The burnt resistor had broken off of the circuit board and was laying inside the cover in 2 pieces. The chip had cracked from the heat and the top half was also found loose inside the cover.

I obtained a replacement board from Sears Parts Direct (best price I could find). Cost was $164 after 15% discount coupon (just Google!) plus tax and shipping, $193 total. Popped the new board in and the machine works great!

We paid $895 plus tax for the machine, and I couldn’t see throwing it out over one little part. Hope to get another 6 years out of it!

Head Wrench

Excellent! Glad it worked out. I did another MCU myself today … also with a blown chip and resistor. Saving the landfills, one machine at a time. lol.

Marvin Casteel

Well I resoldered those traces at the F & I location… no go… well I tried, looking for affordable parts now, wish me luck

Marvin Casteel

Cleaning done, used isopropyl and swabs, scrubbed as best as could. After making sure it has dried off, I noticed that the traces of residue were still visible, even if greatly diminished, this just reinforced my theory that the residue is leftover from the manufacturing process…

Marvin Casteel

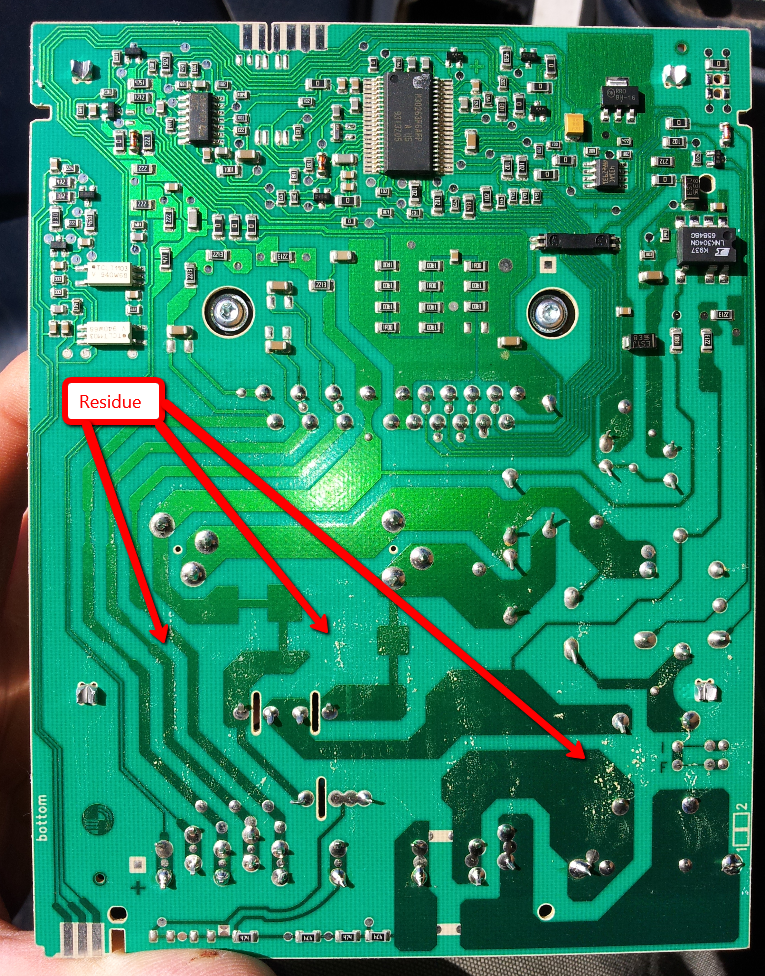

Thank you for this article Head Wrench! Very helpful! I also have this MCU error F70/71 with our washer, I was intrigued by the so called soap trails / residue on the back of the boards in your pics, so when I removed my board I looked for them, and sure enough it’s the same here. But it does not make sense, as someone else noted the residue lines seem to defy gravity as they are horizontal! Also I could see no way for soap or water to get inside the case the board is mounted in, also if this was dried soap from dripping down onto the case and board it should leave residue on the case also but there is none, aside I know for a fact that we have only used HE detergent, but unless we are breaking the laws of physics here, these residue lines are not caused from dripping water / soap! Before I had to retire due to multiple medical issues, I worked many years as an electrical / mechanical drafter and designer, from my experience these residue lines, and they are not all lines on our board there are a few places were the residue has left circular patterns, I believe that these residue patterns we are seeing are artifacts from the cleaning stage of manufacturing these boards, shoddy cleaning I might add, it seems that in the final cleaning when these boards were hung or layer out to dry from the cleaning solution there was still solution left on the surface of the boards leaving this residue when evaporated. Whether or not this residue is contributing to the failures is another story that I don’t have the answer for.

As a couple others have noted burned traces or components, I checked for such also and at first glance could not find any, I double checked using a magnifying glass, found two very small traces located close to the bottom left (when in mounting position) that are labeled “I” and “F” , the one labeled “F” appears to be damaged, I can’t tell if it is burnt or corroded, but one of the two, I am going to clean the residue off the board and attempt to fix the solder trace. Will post back with results…

Head Wrench

Great info Marvin. Thanks!

Damon

I cannot or do not understand why the neg leg trace or rectifier to the capacitor trace keeps blowing after re soldering, as it blows it takes out both traces of thermosistor and blows diode, capacitors good replaced diode twice repaired thermosister traces twice, could the rectifier itself be bad? what would have caused the neg trace of rectifier to blow to begin with? Just curious if anyone knows, I do not have 400.00 to replace this what appears to be 25.00 worth of parts on a circuit board in which I am prepared to replace all if necessary. UUHHGG

Mike

Hello,

I think I may have a MCU problem, however not 100% sure and the board costs approximately $500 Canadian. Here is what is going on,

– Main issue is that the washer will often times, not spin fast enough to get the clothes decently dry to put them in the dryer. It is a front loader, worked fine for 6 years. Washer will drain fine; checked the filter just in case, and nothing to be found. The motor turns the drum no problem, and will advance through all cycles, it’s just the spin cycle that the motor will not get up to SPEED!

Please help, i really don’t want to waste $500 on a part that isn’t the problem

Thank you,

Head Wrench

That is a tough one to say for sure it is a MCU. I would be checking for drag on the tub, bearing issues and other things before blaming the MCU. Hard to do without actually seeing. Sorry.

gilberto calixto

i order parts for my ccu board for my whirpool sport duet ht front load washer as per my technicians advice. errorr code foi is keep coming back , first time it happened to my 5 years old washer, how to install myself is all i need to know, i dont want damaged the new ccu board?

Ben

I have a whirlpool WFW95HEXR2 with the error codes:

F01 E02

F06 e03

Ended up ordering a MCU part # AP6020609 last year and it fixed the problem. However, I have the same error again. I would like to know the root cause of this since 300 dlls on the part itself is costly.

Nick

Hi there Head Wrench! This seems to be the place to go for blown MCUs. I appreciate you keeping the thread alive after so many years, and hopefully you’ll have some advice for me. So I have a Duet HT (WFW9200SQ00) that recently F11’ed on me and led me to a blown fuse trace on the MCU (the big center one to the middle fat cap – http://imgur.com/a/FwYFk). I did have that soap residue on the board when I found it (seemed a likely candidate), and I was going to replace the board anyway so I shorted the trace, but the traces to the smaller cap on the side blew promptly. I ebay’ed a replacement board of the exact same model number, which is almost exactly the same, though it has a couple of extra surface mount components on the back. When I run the washer with the new board though it trips the GFCI breaker, though not when it starts, only when it’s going to move the drum. I checked the motor, 6 ohms on all three pairs, but the breaker only trips when the motor is plugged in to the board. Without taking it out the motor wires look fine, and it’s not seized (http://imgur.com/j6knRrI), so I’m not sure what else to try. You got any thoughts? Thanks in advance!

John

I cannot tell from the pictures if that is a soap residue, however, I will mention that you seem to have lines but the lines are horizontal when the board is mounted. If the problem were soap running down I would expect to see vertical streaks, not horizontal.

Granted, the environment where the manufacturer mounted the board is poor, located beneath the soap dispenser and thus the water feed. Bad environment right there, should have mounted the board at the top of the machine and run wires down.

Jon

F28 error code and no movement of the drum after the door locking led me to inspect the MCU on my 7 1/2 year old Duet Sport Washer (Model # WFW8410SW02) where I found corrosion on the circuit board pads (similar/worse than your photos), and in the MI3 connector coming from the CCU. I replaced the MCU and cleaned the plug, but still no movement of the drum. The motor windings tested good at 6 ohms, and 115 ohms for the tachometer, IAW the tech sheet; and no shorts to ground from any of the 5 pins. I also tested continuity in all wires from CCU to MCU to motor; I used my meter to ensure the motor is receiving power from the MCU at start-up in both normal cycle and diagnostic mode. I also took the belt off to try a run with no load on the motor: it turns freely when I spin by hand, but it won’t turn when power is applied from the MCU.

Before I pay out for a new motor, am I missing something? Can a washer motor read good across the windings but still not function properly? Any advice is appreciated.

Head Wrench

I would be looking at the control before the motor. You should have 120v going to the 2 pink wires and 5vdc going to the 2 outside blue wires on the 3 blue wire connector going to the MCU. I would also check the harness bundle that goes between the MCU and the motor – wires can break in that group and also cause your issue.

Ted

The picture and you guys’ comments are great, it helps me a lot in resolving my problem.

I also fixed the washer by doing what Kevin did to solder two wires which seemed to have broken. The wires originally were very tiny and were labeled as I and F on the right bottom corner of the last picture. Also I re-soldered the minus pin of the rectifier, which seemed to be loose and slightly burnt out . I don’t know what fixed the issue, either or both.

I’m still curious about those two thin wires printed on the board, it sounded like they were meant to burn as a destiny. Anybody got any idea on this?

So, this fixed my Whirlpool Duet Sport washer, Model WFW8300SW02, which had worked fine for 7-8 years. It stopped with 4 mins left on spinning from the last load and the door wouldn’t unlock. I reached the handle in the front to release it manually. The washer then seemed to respond to any button pressing on the panel, but just wouldn’t start any cycle. Also it wouldn’t do diagnostic test at all, I’d tried with and without reaching the historical error messages. Even after the fix, it still doesn’t do test to include the history though the test without history will start fine.

Ted

I also fixed the washer by doing what Kevin did to solder two wires which seemed to have broken. The wires originally were very tiny and were labeled as I and F on the right bottom corner of the last picture. Also I re-soldered the minus pin of the rectifier, which seemed to be loose and slightly burnt out . I don’t know what fixed the issue, either or both.

I’m still curious about those two thin wires printed on the board, it sounded like they were meant to burn as a destiny. Anybody got any idea on this?

So, this fixed my Whirlpool Duet Sport washer, Model WFW8300SW02, which had worked fine for 7-8 years. It stopped with 4 mins left on spinning from the last load and the door wouldn’t unlock. I reached the handle in the front to release it manually. The washer then seemed to respond to any button pressing on the panel, but just wouldn’t start any cycle. Also it wouldn’t do diagnostic test at all, I’d tried with and without reaching the historical error messages. Even after the fix, it still doesn’t do test to include the history though the test without history will start fine.

Amanda de Freitas

Hi Mr. Head Wrench,

I am working on a WP Duet MCU board, I think a resistor (or other component) got fried during a very quick power outage while the machine was running and before I could unplug it before the power came back on, I am pretty sure of the resistor that was affected but after cleaning away the burnt areas on both sides of the board it would seem that I am missing a resistor, I think it may be a 1002 but I can’t find a good enough picture of the underneath of the board to see the resistor number; have searched and search all over the net; and you apparently are the most learned regarding this MCU board, I was wondering if you had a great picture of the underside that holds all the resistors and conductors? You would be St. Head Wrench to me and many others if you had one that you could possibly post?

Bill

I have the dreaded F06 error. Sears came out, says I need a MCU and it’ll cost $422. I’m about to go take the board out and inspect it against your pictures.

Is the refurb board (8181693R) in DavidD’s reply on Sept6 a direct replacement for the board that the Sears guy just told me I need: 8182706? If so, that’s a no-brainer…because I have no idea how to solder. :-/

Also, he told me I should probably buy a new washer; mine is 10 years old and the rear bearing has a little “play” in it. He says *that* repair will cost around $1600!!!

Head Wrench

I’m not sure about your part number question … the ‘R’ at the end of a part number typically stands for ‘rebuilt’ or ‘refurbished’ but the fact that they are 2 different part numbers makes me wonder.

A rear bearing replacement is not worth doing on a 10 yr old machine … but ‘a bit of play’ is also not normally the first thing that shows up in a bad bearing. Usually you will have noise complaints long before any play shows up. If it is getting louder on spin (a roaring noise,) then you have a bearing on the way out – if you don’t have that sort of sound, then I would not sweat the bearing.

Kevin

Mine just burnt out after about 7 years, always used he, never ever regular.

Took it apart and examined closly, it Had soapy buildup aswell, altho im not entirely sure its soap seems more like corrosion off a battery, but i found 1 burnt out trace, its the fine paralell trace showen in the last picture on the lower right hand side, has an f and an I besides it, these seem to be a simple pcb fuse.

I bridged the points with some fine wire and cleaned the board, reinstalled and bobs your uncle it worked!

Nick Nishino

My Duet washer MCU board also indicated a failure? I removed and examined the circuit board and found no soap residue but a blown surface mount resistor. My Duet is mounted on the optional drawer storage bin in my enclosed garage not sure how the soap residue would contact the MCU board hope this info helps to solve that mystery? Replaced the MCU board $240.00 Sears parts warehouse Dallas Texas. Completed the diagnostics test, all clear no error faults detected. Advised my son not to overload our Duet washer, if it fails again he will pay for the repairs.

DaveD

The MCU is prone to failure, such that these boards are now being refurbished. 8181693R from sears parts direct is $100 with a 1yr warranty. This is a simple repair, three screws and the board snaps in and out of the plastic housing which snaps in & out of the chassis. Sears shows almost 1300 of these sold in the past 12 months on their site, with only 90 wiring harnesses sold; F06 -> its the board. Checking the drive motor is simple, pins 1-2, 2-3 and 1-3 should show app 6 ohms. I picked up my board in San Diego at Sears for 10% off and the machine was running same day for < $100.

Keeping your old appliances running is good for the environment. Save a duets, life. My unit is pushing ten years, no reason it wont go another ten. Do the monthly cleaning cycle, use HE and cut the amount of soap. We wasted so much soap, and P&G knows the psychology of concentrated detergent; consumers will use more then needed and they sell more soap; dont be fooled. You only need a couple tablespoons of HE per load. We used to buy Tide non-stop, we were wasting money, leaving our clothings with soap residue and damaging the machines bearings.

Alan

I have a MAYTAG, it stopped working and blew the MCB in the fuse box, when switching it back on it displayed fault code F22 (communication error) I checked comms wires and connectors all OK. I stripped and rebuilt the door switch which was OK. So I pulled the motor and MCU. The motor seemed OK with same ohm reading for each winding connection. The MCU was burnt on the back, leaving a mark on the inside of the cover, three tracks were burnt and two connectors look like they have been burnt back into the board, I cleaned off the board with a cloth and as a quick check I bridged the broken tracks, drilled out the burnt back holes and filled with solder. When I put it into diagnostic mode when it got to the motor turn on point there was a big flash and more evidence of burning across the surface of the board and more tracks burnt out, I think this is more that soap, what do you think? Is it likely to be repairable at a sensible price?

Regards Alan

Head Wrench

Hi Alan – It’s really hard to speculate. My thought is that simply repairing the burnt traces on the board did not actually repair the board – it just fixed the result of the bad board. My experience and gut tells me it needs a new MCU. That is probably all it needs especially since you ohm’d out the motor and it tested good. Make sure you check the motor windings to ground as well. Check the price of the MCU here: RepairClinic.

Alan

Many thanks for taking the time to reply Head Wrench. I am inclined to agree with you about needing a new board, I think the problem stems from my wife overloading the machine, so the inverters could have got cooked, do you know if they are in the large black rectangular box on the board? No motor short to ground.

My wife has gone out and bought a Bosch, so I have time to try and fix it. The link to find the part didnt seem to work, a board repair is $125 on one website with no gauranee that there are no other faults with the machine. Whirlpool want around $200 for the repair with a 90 day warranty but I dont really want to pay this much for a fix as used machines sell for this amount, so it would not be cost effective. I am wondering if there is a market for a high power generic motor controller/programme selector.

Regards Alan

Weig

Thank you for you pictures.

I had the same problem. Took me 2 days to find out it is the MCU. I took my MCU out, it looks the same as in pic 1, 3 and 4. I cleaned the MCU, worked for 2 cycles, failed again. Then I baked the MCU in the oven at 385F for 8 minutes, just like what I did to my video card. Now it is back to life.

Anuj

Having the same issue with the mcu. I took it out and the residue is there but no burnt out spots. How did you go about cleaning the board to make it work again? Did any of you fix the board without soldiering anything? Thanks in advance for the help

Jim

I had the same problem. I replaced the CCU and things still didn’t work properly until I came across this site. One of the legs of the bridge rectifier on the MCU had a burnt out solder point. I re-soldered it and it works again. Strange how this seems to be a common problem. I don’t have any wetness or dirt inside the machine (where the parts are) so I don’t see how this is happening. Thanks again for posting this information!

Jim

vince

Ibid to what John Ellis said. I stumbled on your website and after reading about the soap residue on the Duet MCU decided to clear the codes and give it one more try ensuring my wife uses only HE detergent. Machine is only 2 years old and looks reasonably well built. Thanks again for your excellent web presentation.

Vince

Boston

john ellis

I just paid $133 for a lesson that directed me toward the MCU being faulty. Of course it was fine while the tech was here then immediatly died once he left. The option of replacing a $250 MCU only 3 yrs old did not sit well with me so i started to dig and found your web page. The 3 pix you show was what led me to the solution – the soap (or whatever the white trails are) was the culprite, which actually ate through one of the fine board traces that are seen near the top left corner of your last pic. So, I cleaned up the board, soldered a new trace wire and bingo all is well.

I can’t quite get my head around how the soap (if it is soap) gets in the MCU housing in the first place, since it seems sealed to contaminates on the trace side of the board. The other odd bit is that even in your pix the soap trails seem to defy gravity. If the boards you show are the same as mine, with the board sitting in a landscape position when installed, how does the soap leave trails as if the board is installed in a portrait position? Makes no sense.

Irregardless your web page saved me $250. It’s refreshing, and rare now a days, to find some one like your self that wants to know why a problem has occured and share your findings with people that wish to FIX the item rather than just replace parts.

My hats off to you mate!

Head Wrench

You’re very welcome! Glad it helped you and thanks for the kind words!

shawn

i have this problem. after seeing this post i removed my mcu and it had soap residu all over it………no burn marks though. did you replace the mcu in the top picture with success. i have an f70 error which says nothing about the mcu, but when i remove the mi3 the washer powers up, which i believe points to the mcu. any ideas on how much this part is and should i bother replacing it, if yes how can i prevent this problem from happening in the future.