Repairs

Tips and Advice

-

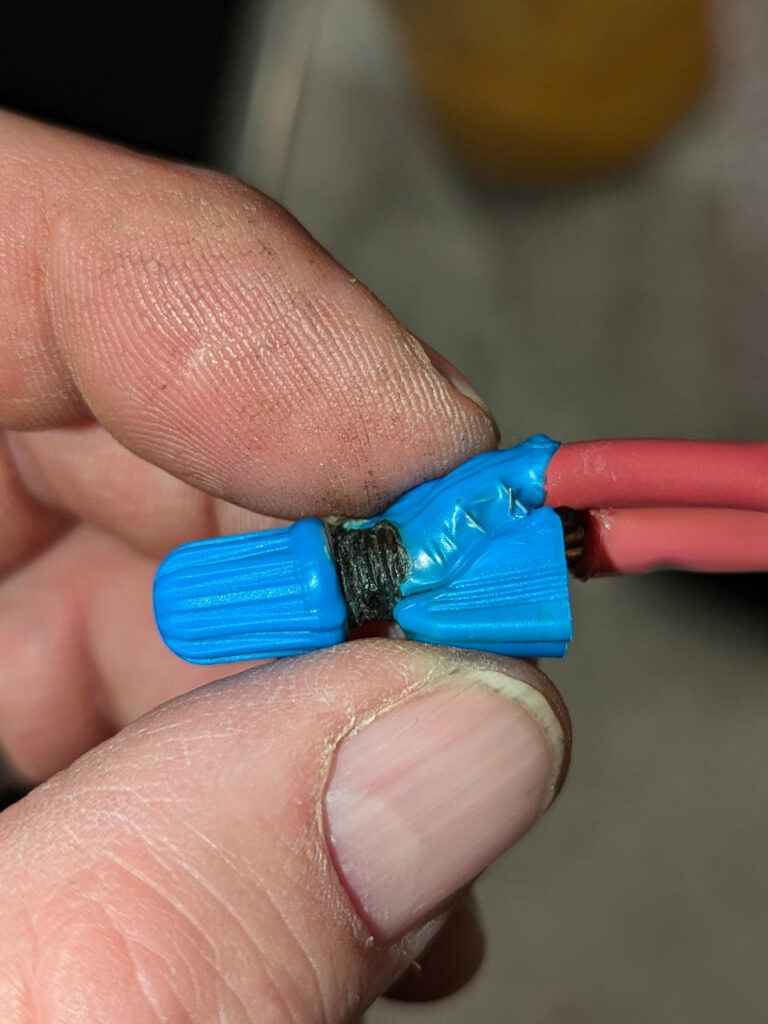

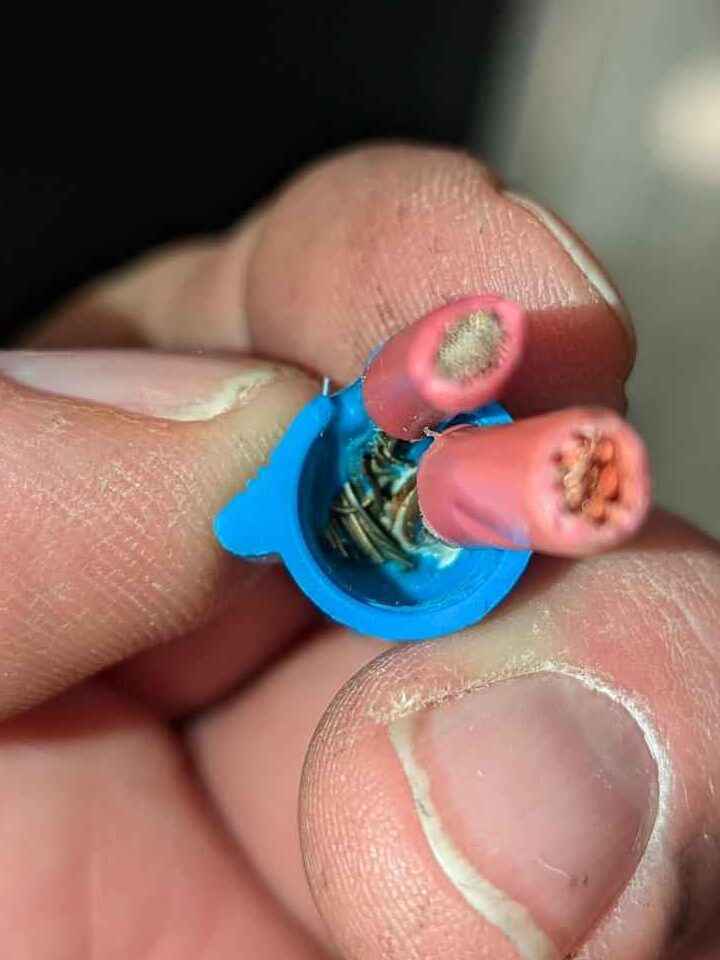

Poor Install. Potential Fire

This repair was a Frigidaire Double Wall Oven with a blown control. I had not discovered the cause of the blown control, but after replacing it found I was missing power on one line. When I was not able to find the source of the issue, I eventually decided to pull the oven and check the electrical supply. This is what I found.

The electrician/installer 8 years earlier had used the wrong wire nuts and when he twisted them on, he pushed most of the wall oven wire strands out of the physical connection. There was enough contact for the oven to work but over time the amp draw through these poor connections began to heat up and melt out the nuts and eventually enough carbon built up to break the connection. The only thing that saved this customer from a house fire was the metal junction box (which curiously was also not correct = the installer used a Hexagonal Junction Box instead of the correct 4×4 Junction Box.)

Hiring the cheapest electrician (or appliance repairman) is not always the best option.

-

Interesting Home Repairs

We see all kinds of home repairs in our travels. Some done well, others … not so much.

This was an interesting one. The owner had purchased an universal bake element but it had screw terminals instead of spade terminals. Instead if swapping the terminal ends, he pried open the spade ends to create something for the screw to hold on to.

It didn’t work. The terminals fell free causing the bake to not work. We added the proper ring terminals and got this Sears unit up and running again.

Good to go for a few more years.

-

Occasional Leaks from Whirlpool or Maytag Front Loader Washer

Machines that leak on one load but not the next can be very difficult to diagnose. Here is one of the more common ‘occasional’ leak sources on older style Maytag or Whirlpool front loaders of the Epic Z or Duet line.

The hose from the fill drawer to the front outer tub gets stiff and no longer seals at the front of the tub. This will usually only leak on loads that hold a lot of water as they spin up to speed like bedding or towels. It probably drips on smaller lighter loads but not enough to see water on the floor. The telltale sign of this leak is rust on the left side of the basepan and goop round the collar of this hose where it attaches to the outer tub.

This is the hose:

The leak happens around this collar:

The repair is to just replace the hose. I’ve not had a lot of success trying to reseal them.

Just another item to add to the list of random leaks when diagnosing these machines.

-

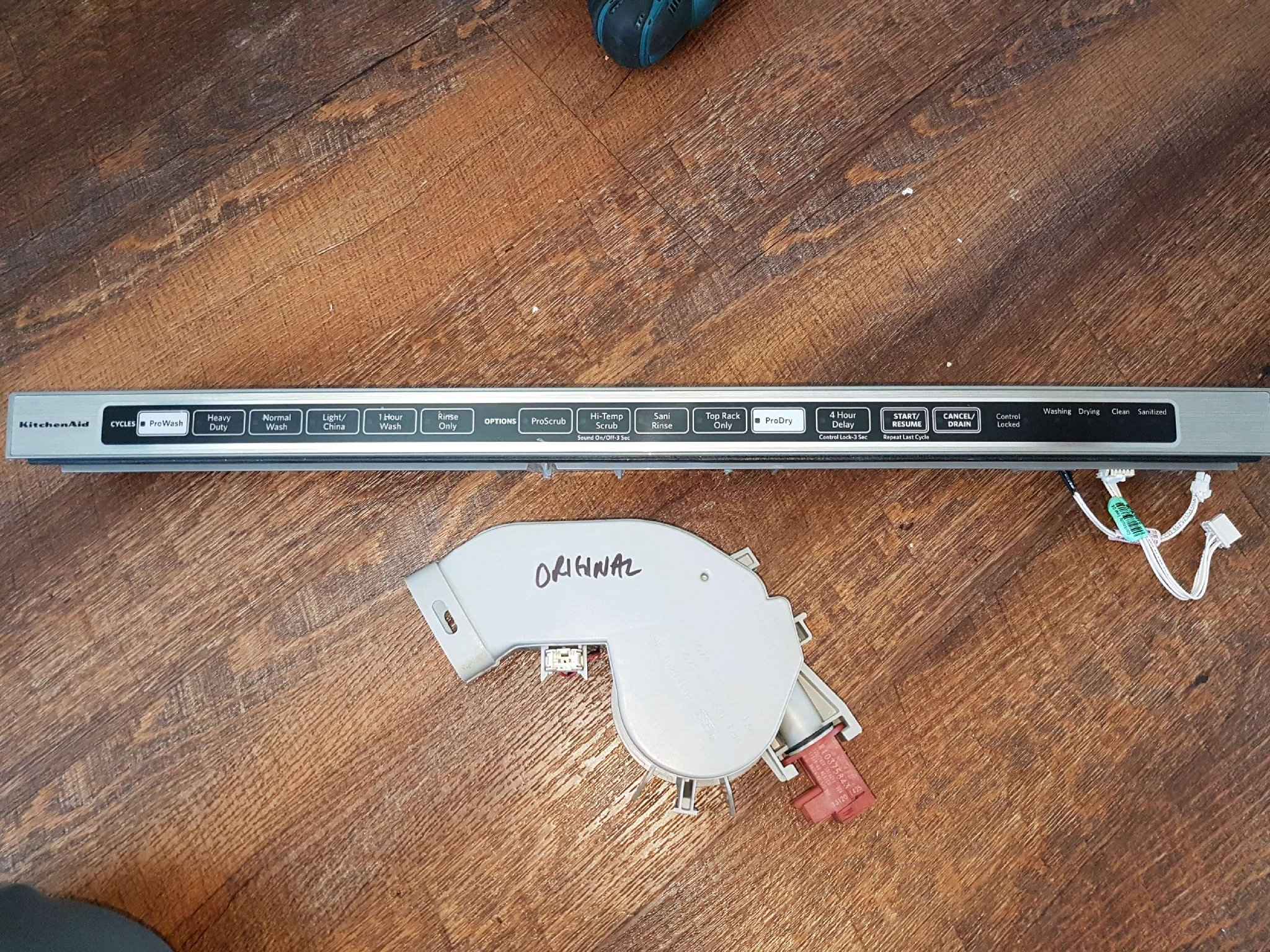

Dead User Interface on Whirlpool Maytag Dishwasher

1st time I’ve seen this, so hopefully this helps other repairs out there.

This is on the Whirlpool line of brands integrated dishwashers with the fan assist dry. Mine happened to be a KUDE70FXSS5 but any in this line with fan assist dry could have this issue.

Dead User Interface Touchpad.

No lights, no beeps. Check for power going into the touchpad 5 vdc. If you have power, then your UI is dead. But why?

Ohm out the dry fan motor on the top left side of the door. In my case it went between high resistance and open, my meter could not lock onto it. Over time this amp draw during the dry cycle can take out the User Interface. If you are lucky, you can just unplug the fan motor and the UI will light up again, but in my case the UI was toast.

If your fan motor is out of spec change it to complete this repair without having to worry about a callback some months down the line.

-

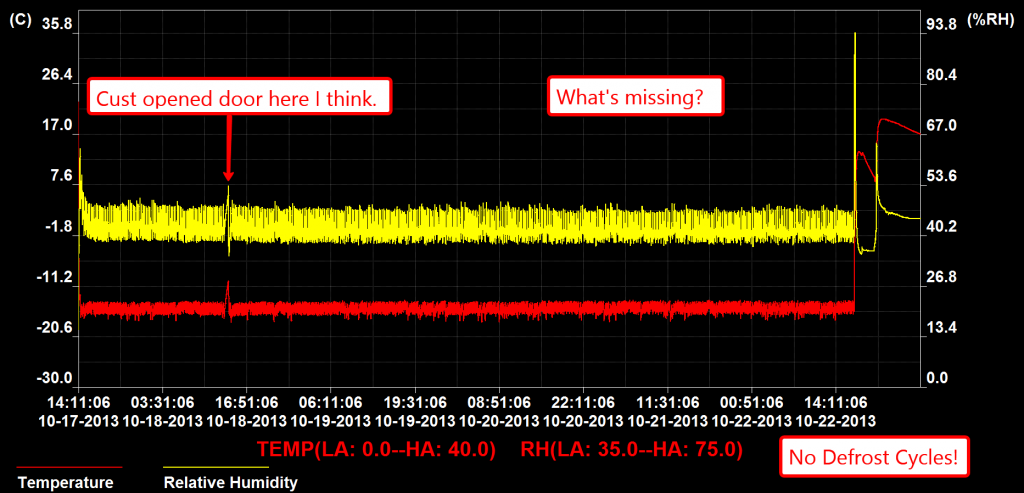

Using a Temp Recorder For Fridge Diagnosis

I had a Whirlpool Freezer that was giving me a bit of trouble with the diagnosis. This freezer was stuffed completely full with harvest goods and the customer was really getting worried that stuff was not cold enough. After getting his food into a loaner freezer, I put a temperature recorder into it for 5 days to see what was happening (or in this case, not happening.) Below is a graph of the temperatures and relative humidity in this unit.

… oh look – No defrost cycles!!

A freezer like this defrosts every 6 to 12 hours based on a timer. In this case there are no associated rises in temp or relative humidity that would indicate a defrost cycle. When I was testing this unit, I could put it into defrost manually, so I know the defrost circuitry is good, the only part left is the defrost timer = easy repair!

This is the temp recorder that I use:

If you want to get a recorder for this type of work, this one is basically the same unit and is available from Amazon: Extech RHT10 Humidity And Temperature USB Datalogger

-

How To Test a Whirlpool Duet Washer Motor

This video shows how to test a Whirlpool (or Maytag, Amana, Inglis) Duet style washer motor with the integrated MCU (Motor Control Unit.) The MCU used to be separate from the motor, but is now attached to the back of the motor. Testing is very much the same as when the MCU was a separate device, but I thought I would show testing on the newer style with the MCU attached.

WARNING!! This is a live test – that means that there is power (which can hurt you) and the belt, pulley and motor may spin (which can also put a world of hurt on you!) Be aware of what you are doing and where you are at while doing these tests. I accept no responsibility for any problems you encounter if you attempt to do this yourself. That being said – Enjoy!

httpvh://youtu.be/USwxpyS151A

-

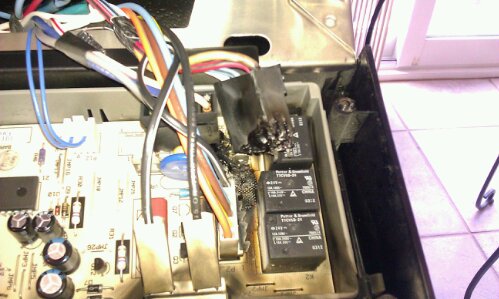

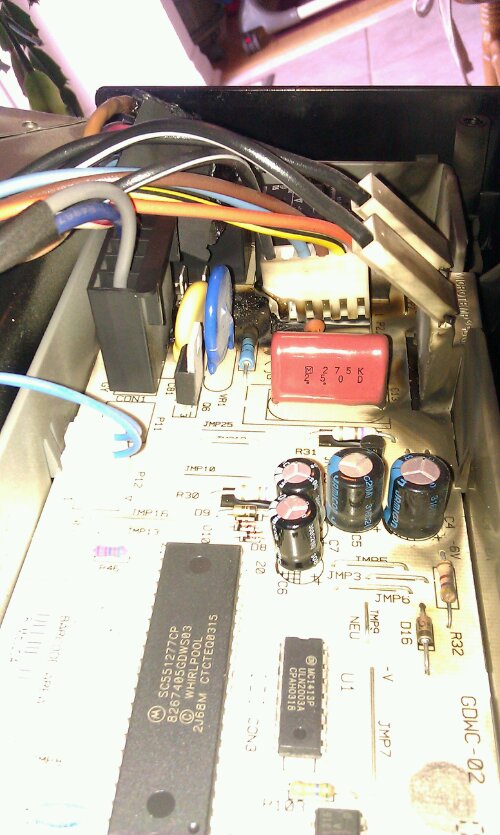

Dishwasher Fire: Close Call

This one was a close call! This control board was smouldering along nicely until the thermal fuse opened and cut the power to the control panel. That’s exactly what that safety fuse is there for – it did its job. I can’t for the life of me understand why there are tech’s out there who simply bypass them. Crazy.

-

Shipping Bolts

This is what the back of a washer looks like when you run it for a couple of years with the shipping bolts in place.

-

Freon Leak

Yep – that’s a Freon leak! Replaced the rotten line and the customer is back in business with a cold fridge.

-

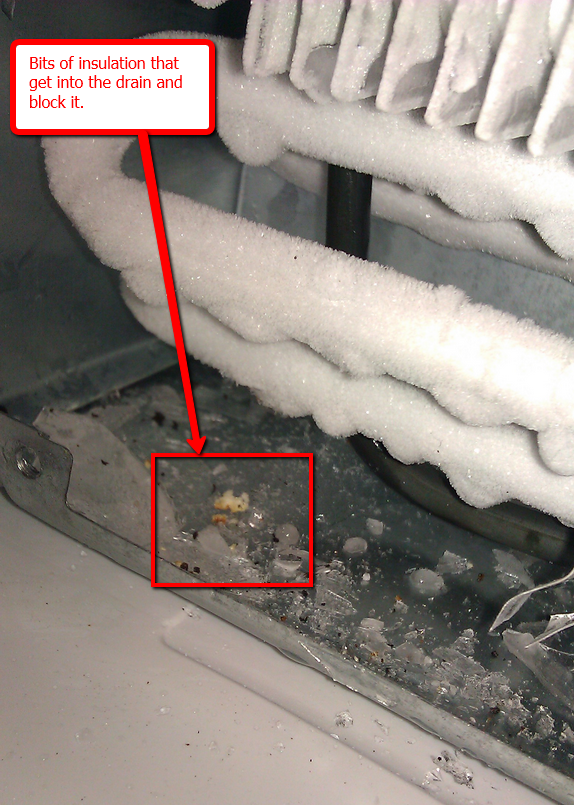

Bottom Mount Whirlpool Fridge Leaking Water

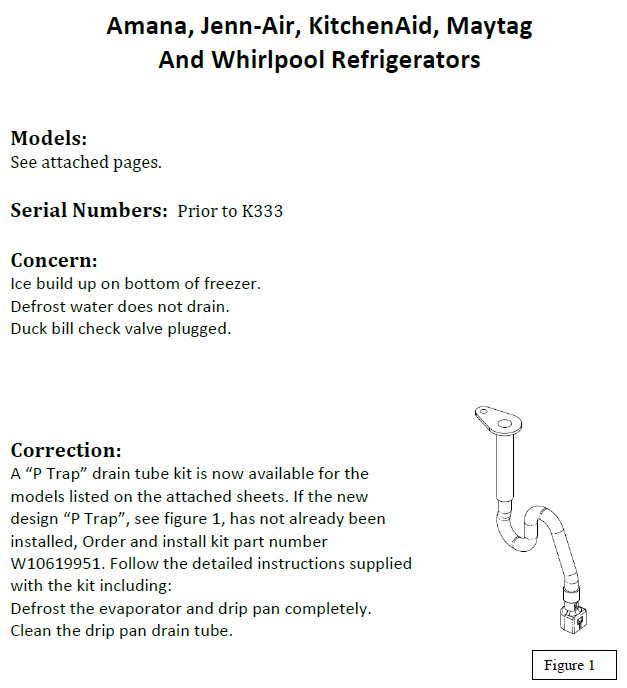

EDIT: New Whirlpool Refrigerators. The issue described below was resolved on the assembly line at Whirlpool at least 2 years ago. New Whirlpool refrigerators have different drain systems. This does not mean that they will never have a drain problem = since the invention of the self-defrosting fridges we’ve been fixing plugged drains, but it does mean that the problem outlined is no longer an ongoing issue on new fridges.

If your Maytag or Whirlpool bottom mount fridge is leaking water, it might have a blocked drain in the freezer section. The symptoms typically are periodic water on the floor in front of the fridge and a sheet of ice in the bottom of the freezer. The way the defrost system works is: every 6 to 8 hours we turn on a heating element in the freezer section to melt any frost build up on the evaporator. This water drips down into a trough and then drains via a tube to the drain pan in the bottom of the fridge where it evaporates away. When that tube gets blocked, the water backs up into the trough in the freezer eventually spilling down into the bottom of the freezer where it freezes.

There is only one way to repair this problem properly so that the problem does not come back … just defrosting the unit is not a perminment repair (just a hint to those companies that I’ve been following around these days.)

What usually happens is something gets caught in the grommet which is attached to the bottom of the drain tube. (The grommet is the soft black rubber ‘duck bill’ valve that is slipped on to the bottom of he drain tube that prevents warm air from migrating into the freezer – more on this later.) The blockage could be a gummed up spill (like milk), a pea, bits of bread crumbs or anything else that could be carried into the drain. What I’m finding a lot of is bits of insulation from the manufacturing process ending up in that grommet. This blockage holds water that begins to freeze and eventually creates a dam and complelely blocks off the drain … and then you end up with water on the floor.

Here is a picture of a big chuck of insulation that was caught in the ice that was built up in the drain trough.

Chunk of insulation in drain trough. Here are more bits of insulation in the drain trough. These bits flow into the drain tube and are caught by the grommet eventually blocking it up.

More bits of insulation in the drain trough. This is what the grommet looks like with bits of junk and gummed up gunk in it.

Grommet with bits of insulation trapped in it. How to Repair

The only way to properly repair this is to clear all the ice out of the trough and drain tube. Then remove the grommet from the bottom of the drain tube (accessed from the compressor compartment), clean it out and trim it open a bit. This is the part of the repair where things might get a bit dicey. Whirlpool will NOT want this done! What the grommet does is prevent the freezer from equalizing the air pressure through the drain tube when the freezer door is shut. If the grommet is not there, then when the air pressure equalizes, it will draw warm moist air through the drain tube which coats the evaporator and can cause potential moisture issues in other areas. The trouble is: the grommet opening is just a slit and is easily restricted. This is causing multiple calls for the same issue (blocked drain causing leaks.)

So what to do?

Here is what I do. I trim the end off the grommet. This allows the water to flow out more easily and helps prevent blockages while at the same time still restricts air from free flowing into the freezer through the drain tube. I’ve gone back to a number of fridges where I’ve done this repair and rechecked the evaporator and have not found any excessive frost or moisture, so I’m confident that I’m not causing other problems by doing this. However … this is not the official repair, so do at your own risk.

Here is what the grommet looks like trimmed.

If you are fixing these some other way, I would love to hear about it … always looking for new ways to do repairs!

Update!

EDIT: Since I made this post, Whirlpool has come out with a ‘official’ repair for this problem. It involves a new ‘p-trap’ which replaces the ‘duck-bill’ grommet that was getting full of junk and sticking together. Even with this p-trap repair being available, if you want to do the repair yourself and don’t want to pay a Whirlpool certified repairman, the above repair works just as well. I’ve never had a callback on this repair, and I’ve done it dozens of times, so you can have confidence with it. That being said, here is the info on the repair kit from Whirlpool:

My understanding is that the part will be provided at no cost for up to 2 years from the date of purchase. Visit Whirlpool.com for more information.

Edit … Part Deux!!

Here is a video of how to install the new drain tube. It’s pretty easy – should only be about a 15 minute job. Don’t forget to clear the ice out of drain at the back bottom of the freezer section … otherwise the water will continue to leak even after you’ve completed the repair (either the ‘snip’ or the drain tube install.)

httpvh://www.youtube.com/watch?v=7akWydOJyhc

Edit … Part 3 The Final Chapter! (Maybe. lol.)

Here is a quick cautionary video showing how easy it is break the drain pan. Don’t crack it = you will NOT like that repair if you have to replace it. (Glue does not work!) You want to work out the old trough by pushing on the tab, not just bending it or ripping it out.

httpvh://www.youtube.com/watch?v=iCdaghxERAY