-

Poor Install. Potential Fire

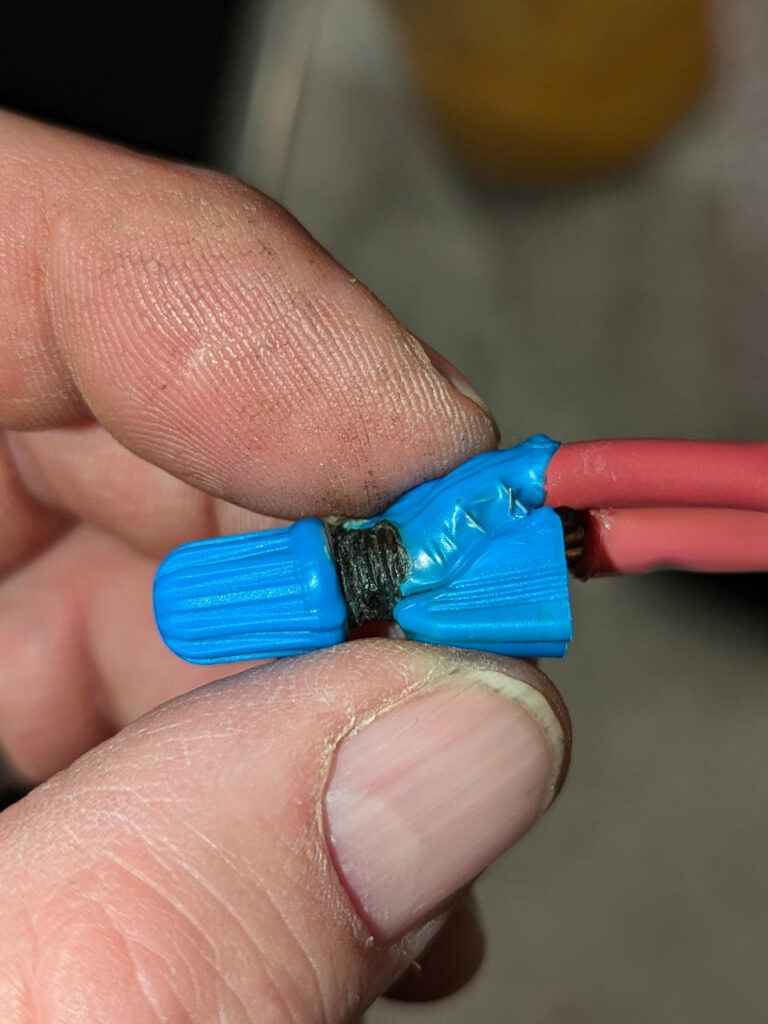

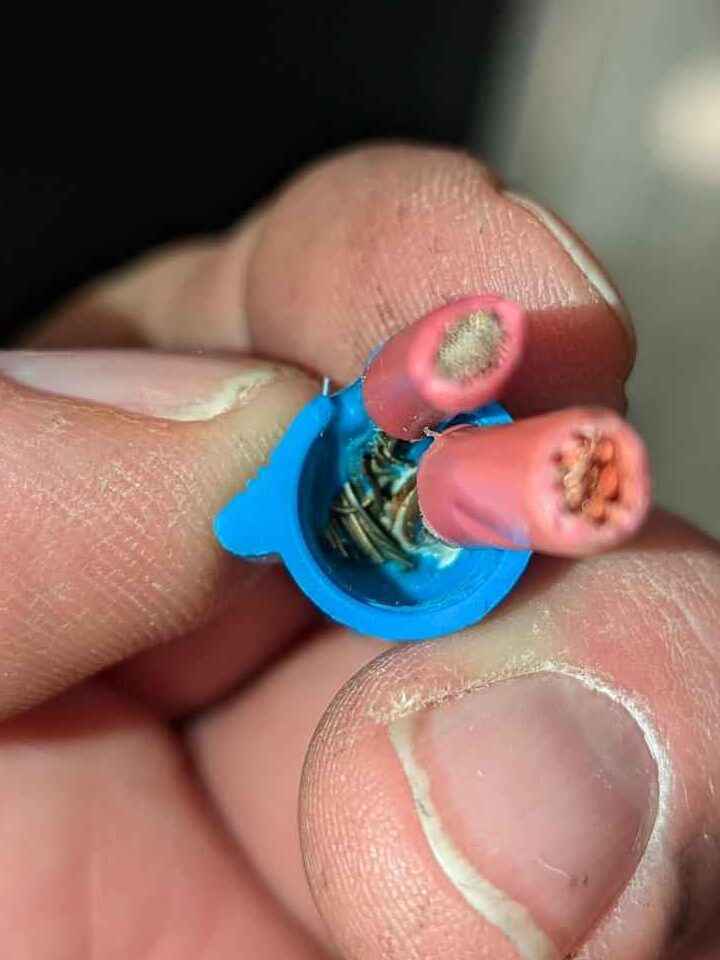

This repair was a Frigidaire Double Wall Oven with a blown control. I had not discovered the cause of the blown control, but after replacing it found I was missing power on one line. When I was not able to find the source of the issue, I eventually decided to pull the oven and check the electrical supply. This is what I found.

The electrician/installer 8 years earlier had used the wrong wire nuts and when he twisted them on, he pushed most of the wall oven wire strands out of the physical connection. There was enough contact for the oven to work but over time the amp draw through these poor connections began to heat up and melt out the nuts and eventually enough carbon built up to break the connection. The only thing that saved this customer from a house fire was the metal junction box (which curiously was also not correct = the installer used a Hexagonal Junction Box instead of the correct 4×4 Junction Box.)

Hiring the cheapest electrician (or appliance repairman) is not always the best option.

-

Interesting Home Repairs

We see all kinds of home repairs in our travels. Some done well, others … not so much.

This was an interesting one. The owner had purchased an universal bake element but it had screw terminals instead of spade terminals. Instead if swapping the terminal ends, he pried open the spade ends to create something for the screw to hold on to.

It didn’t work. The terminals fell free causing the bake to not work. We added the proper ring terminals and got this Sears unit up and running again.

Good to go for a few more years.

-

My Boy is Learning

-

No New Posts But Still Working Hard

I’ve received a couple of inquiries about our business as we’ve not been updating the ‘blog’ here for the past couple of years. While we should be adding interesting bits to the blog … and maybe we will start up again, we are still very much in business and working hard keeping appliances up and running in our part of Southern Manitoba.

Covid has been a real monkey wrench in the works and we very much want to see all our friends and clients safe and healthy. We are doing our best to work with the restrictions put in place by the local and federal governments but we are also cognizant of the fact that health is a personal matter. We will not ask questions about your health care status other than whether anyone is currently ill, under quarantine or recently exposed. These questions help us to stay healthy and hopefully not carry the C to our or your homes.

Kindness and friendliness are free and we try to employ these before all other measures.

Thanks for your patience and understanding!

-

Occasional Leaks from Whirlpool or Maytag Front Loader Washer

Machines that leak on one load but not the next can be very difficult to diagnose. Here is one of the more common ‘occasional’ leak sources on older style Maytag or Whirlpool front loaders of the Epic Z or Duet line.

The hose from the fill drawer to the front outer tub gets stiff and no longer seals at the front of the tub. This will usually only leak on loads that hold a lot of water as they spin up to speed like bedding or towels. It probably drips on smaller lighter loads but not enough to see water on the floor. The telltale sign of this leak is rust on the left side of the basepan and goop round the collar of this hose where it attaches to the outer tub.

This is the hose:

The leak happens around this collar:

The repair is to just replace the hose. I’ve not had a lot of success trying to reseal them.

Just another item to add to the list of random leaks when diagnosing these machines.

-

Don’t Be This Appliance Repair Guy

Unfortunately, it is very difficult for consumers to know whether their appliance repair person is a good tech or not. On-line ratings are helpful, but often don’t tell the complete picture either as they really just reflect how good that person or company is at managing their on-line presence. So this post is more for repair guys = don’t be this kind of appliance repairman!

Background: I follow a bunch of appliance repair ‘help’ sites and a few Facebook Groups. I sit here and shake my head sometimes at the absolute and utter nonsense that I read from ‘professional’ appliance repair technicians. This morning I read advice about a very common repair that shakes my faith in my fellow repair guys.

The Appliance and Repair: There are a certain number of models of Whirlpool Top Load Washers that occasionally have issues with the drum bearings. (All washers have bearings and all bearings can and do break. Whirlpool is about the only brand that makes a washer where the tub bearing is somewhat economical to replace.) In this discussion, ‘professionals’ were talking about the kit that Whirlpool has produced that replaces the bearings and the shaft that go bad on these units.

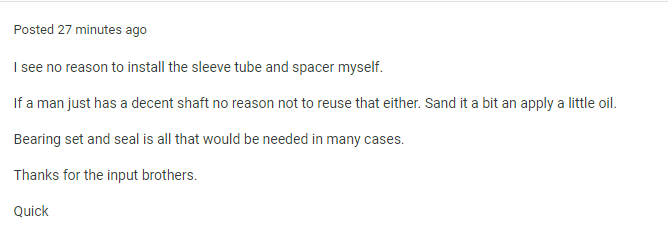

Don’t Be This Guy: This gem comes from one of the guys giving advice on this forum:

This ‘professional’ literally throws out 3/4’s of the parts that come in this kit that the manufacturer has made available for this repair! = including the shaft which the bearings ride on … that is ALWAYS scored and chewed up. Unbelievable! And this guy is giving advice to other repair guys!

Understand this: installing the sleeve tube, spacer and shaft takes NO EXTRA TIME!! This guy just knows better, and chooses to not install these parts. I’ll bet he charges for the full kit too. Shameful.

My fellow repairpeoples … don’t be that guy. Cutting corners and doing temporary ‘repairs’ hurts all of us. We all look bad when you do this garbage. Take pride in your work. Take pride in your repair.

For those of you wondering which bearing I’m talking about:

-

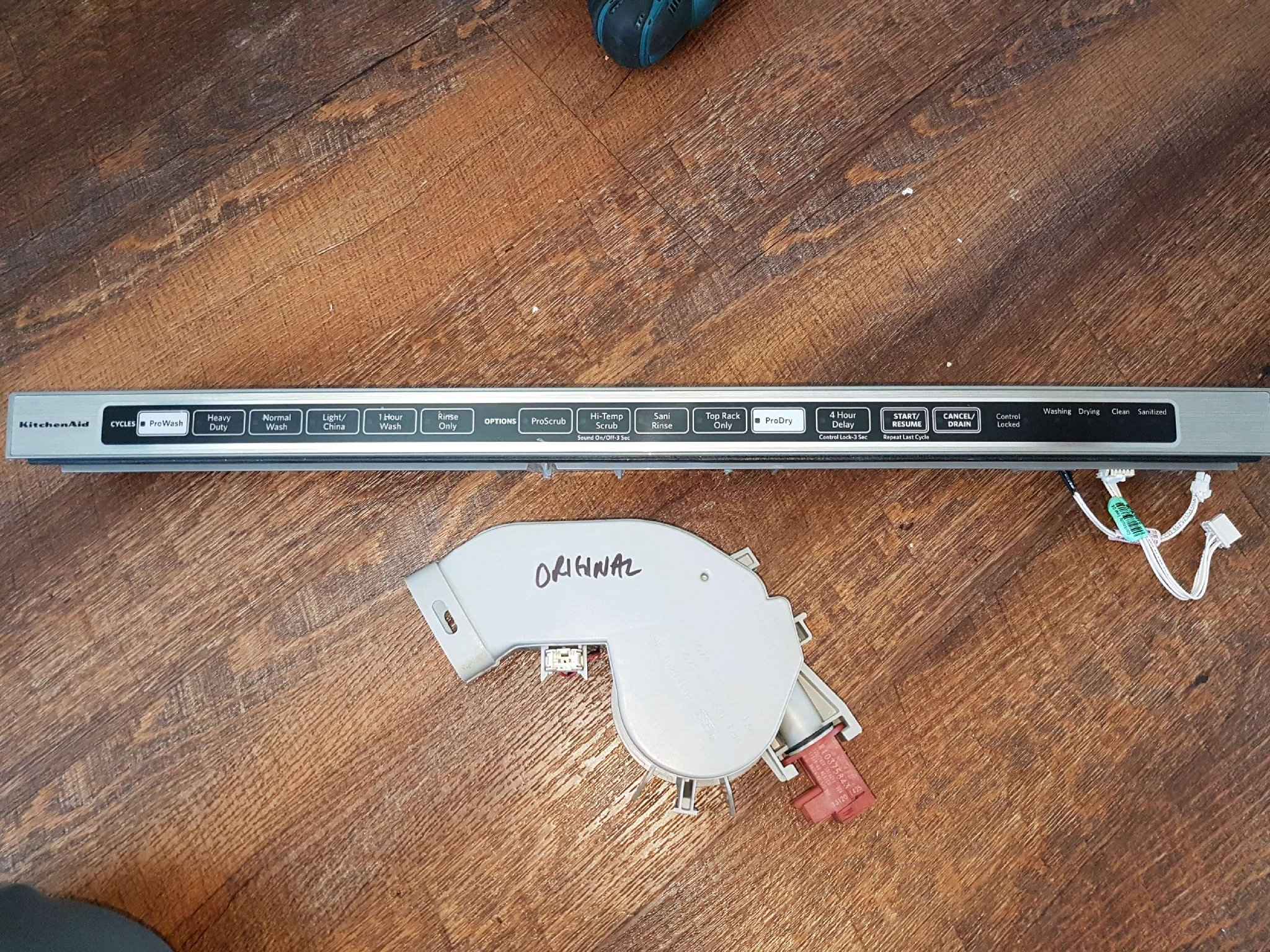

Dead User Interface on Whirlpool Maytag Dishwasher

1st time I’ve seen this, so hopefully this helps other repairs out there.

This is on the Whirlpool line of brands integrated dishwashers with the fan assist dry. Mine happened to be a KUDE70FXSS5 but any in this line with fan assist dry could have this issue.

Dead User Interface Touchpad.

No lights, no beeps. Check for power going into the touchpad 5 vdc. If you have power, then your UI is dead. But why?

Ohm out the dry fan motor on the top left side of the door. In my case it went between high resistance and open, my meter could not lock onto it. Over time this amp draw during the dry cycle can take out the User Interface. If you are lucky, you can just unplug the fan motor and the UI will light up again, but in my case the UI was toast.

If your fan motor is out of spec change it to complete this repair without having to worry about a callback some months down the line.

-

Do HE Washers Really Save Money?

There are a lot of cynical opinions about newer style washing machines – how well they are built, how long they will last and more importantly how much money they save (or don’t save) in water useage. I know they use a LOT less water, but I was unsure about what the actual savings were. So I dusted off my calculator, licked the ‘ol pencil tip and did a few calculations. Here’s what I came up with.

First some stats: (Data from Energy Star Site)

Old style, full size washers … the ones that filled up with water each load, used about 25 gallons per load. That is an average number – some were less, and some were more – but the average water usage was around 25 gallons.

The average family with 2 adults and 2 kids does about 10 loads per week. That number is based on my own experience for what it’s worth …

So, the first calculation is: 25 gallons x 10 loads per week = 250 gallons per week x 52 weeks in a year = 13,000 gallons of water per year used to run your old standard sized washer.

OK – lets look at HE (High Efficiency) washing machines.

Energy Star washers (the best of the High Efficiency washing machines) use about 13 gallons per load.

Calculations: 13 gallons x 10 loads per week = 130 gallons per week x 52 weeks in a year = 6,760 gallons of water per year used to run a HE washer.

OK – so what does that mean in terms of cold hard cash??

Here in Southern Manitoba I pay $13.80 per 1000 gallons of water.

So lets do some more figuring:

Old Style Washers = 13,000 gallons per year x $13.80 per 1000 gallons = $179.40 per year in water.

New Style HE Washer = 6,760 gallons per year x $13.80 per 1000 gallons = $93.29 per year in water.The average washer should last about 15 years …

Old Style Lifetime water cost = $2691.00

New Style HE Lifetime water cost = $1399.32That is a savings of $1291.68 over the lifetime of your washing machine!! And this does not even include the electrical energy savings!

So when some jaded, cynical old codger tells you that there is no real savings in HE washing machines, you can call him out with cold hard numbers … and money in your pocket!

EDIT: Many HE machines are now also limiting the amount of hot water used per load by reducing the water temp on the initial fill and using cold water rinses. Of course, not everyone is happy about this (for reasons I truly don’t understand,) but there are more energy savings to be had here as well. Tricky to calculate but will amount to a decent amount of savings when you combine with the reduced water usage.

-

Burning Smell Coming From Inside Dishwasher?

If you’ve got a burning plastic smell coming from your dishwasher, the first thing to check is if something has fallen on the element. I find all kinds of things melted onto the elements including plastic utensils, straws, Tupperware lids, etc. In this case the rinse agent cap had not been tightened up properly and it fell out and melted.

-

Brand New Dishwasher Not Draining

About 95% of the time when I’m called out to fix a brand new dishwasher that is not draining, the problem ends up being related to the install.

I occasionally see crushed or kinked drain hoses but most often it is due to the knockout not being removed from the drain stub in the plumbing under the sink. Or, if hooked up through a garbage disposal = same thing. The knockout still in place.

This is a knockout that I removed from a garbage disposal yesterday. Not covered by warranty either so the dishwasher install just got a lot more expensive.